Standard Equipment

- Analytical balances, precision balances, moisture balances

- Soxhlet and Perforator extraction systems

- Vacuum filtration systems

- Rotary evaporator (Heidolph)

- Climate chamber (Voetsch VC- 4150) with IR and UV irradiation

- Muffle furnace (Heraeus) PID controlled

- Fume hoods

- Magnetic stirrers

- Hydraulic heated press 35x30cm with PID controlled temperature, controlled thickness and pressure

- Drying oven (Binder) PID controled

- Particle drying chamber

- Flat die pellet press (6mm)

- Resin mixer/blender

- Wood hammer mills and disc flaker

- Portable wood crusher

- Sieve shaker and analytical sieves

- Universal testing machines: 4t (Amsler) και 30t (Shimadzu) equipped with large variety of loading fixtures

- 1m3 formaldehyde and VOC emission chamber (Voetsch)

- 0.125m3 conditioning chambers with saturated salt solutions and on-line acquisition of climate conditions (RH/T)

- IKA overhead stirrer

- Water distillation unit (GFL)

- UV-VIS spectrophotometer (double-beam) (Hitachi)

- Laboratory mill (Willey)

- Stirrer-mixer (ΙΚΑ)

- Cold pre-pressing systems (pneumatic)

- Machinery for mechanical processing wood and wood products (circular saws, band saws, planer, thicknesser, sander etc.)

- Hydrothermal treatments reactors

- Non-destructive high-frequency scanning device for determining density profiles in solid wood

- Viscometers (Brookfield and ford cups)

- Surface roughness measuring device (Mitutoyo)

- pH meter (Crison)

- Water baths PID controlled

- Laboratory glassware

- Pelletizing press

- pellet mechanical durability determination device

- Impregnation chambers ((1, 50 and 500L)

- 10mm single die pellet press PID densification temperature control

- 2L glass reactor (pyrex)

- Pellet mechanical durability determination system

- Various micrometers (Mitutoyo, Insize etc)

- Stainless steel reactors (50L and 1L)

- Wood resistance moisture meters (Gann)

- Wood surface density scanner (Lignostation)

Special Equipment

Laboratory Heated micropress Video

- Dimensions 120x120mm

- Plate temperature up to 350ºC

- Individual plate heating with PID control

- Adjustment to test machines for precise control of pressure and thickness

- Possibility of adjusting the distance mechanically (with spacers)

- Stainless steel coolers

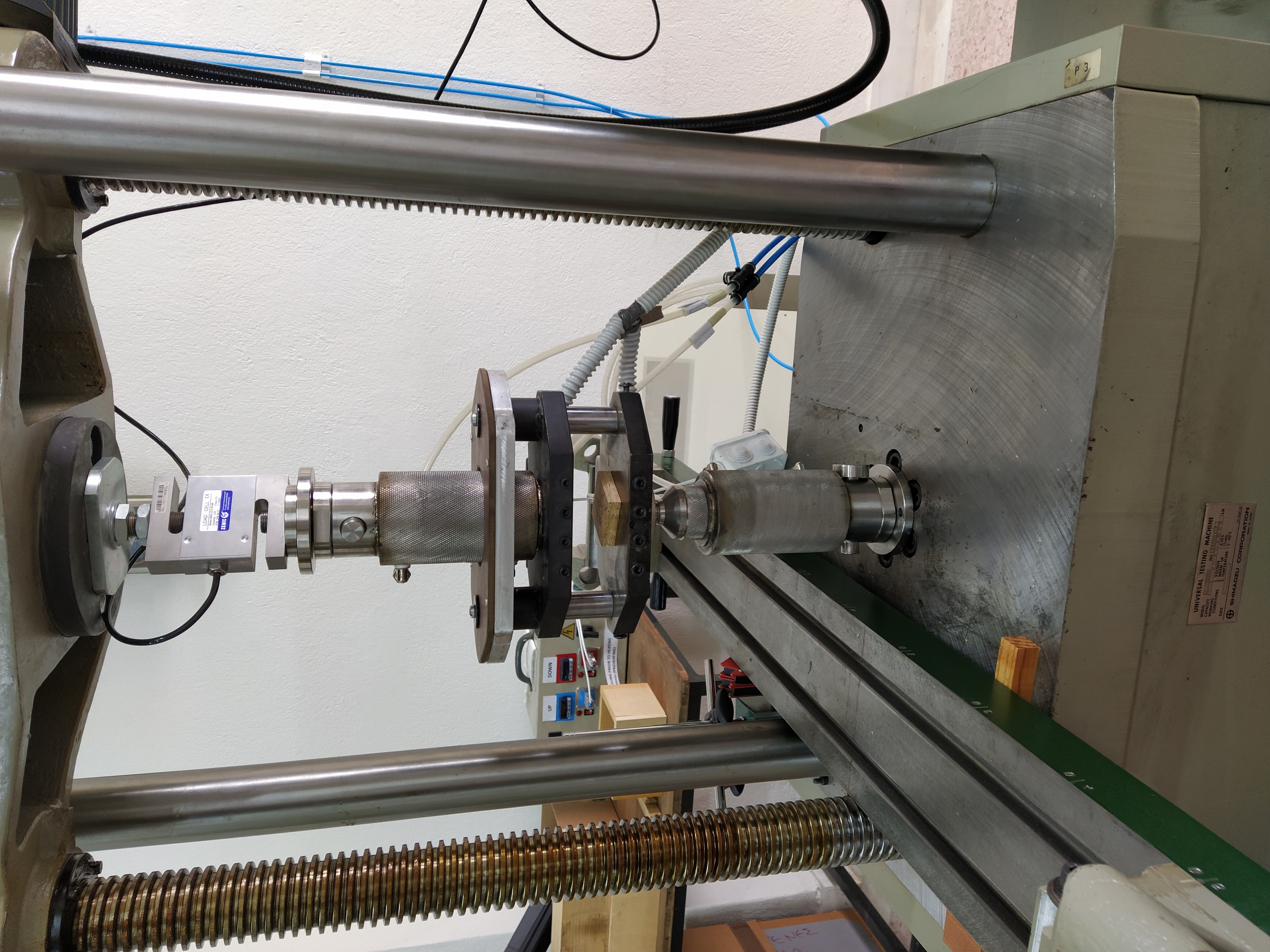

Mounting of micropress on a Shimadzu hydraulic testing machine for open system densification

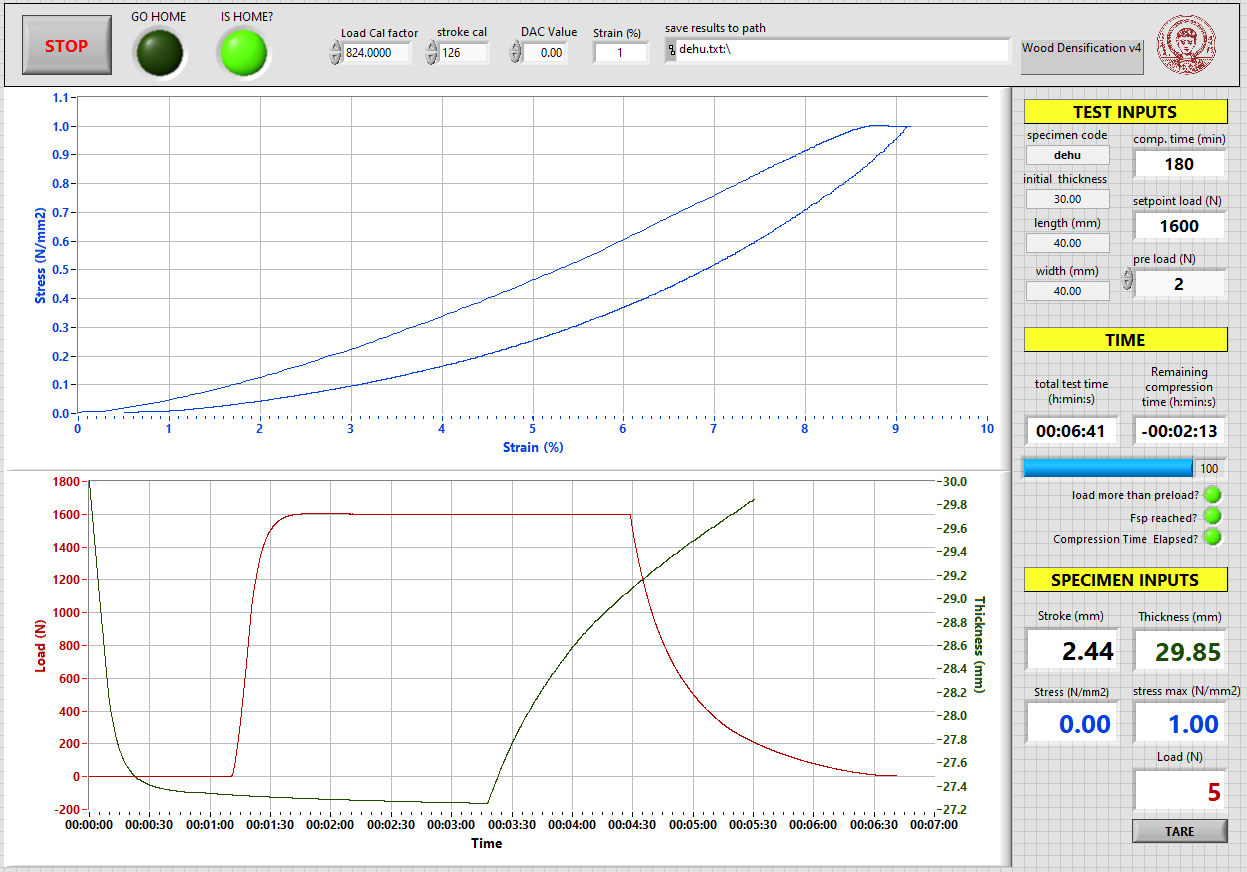

Data aquisition and analysis during open system thermomechanical densification of solid wood

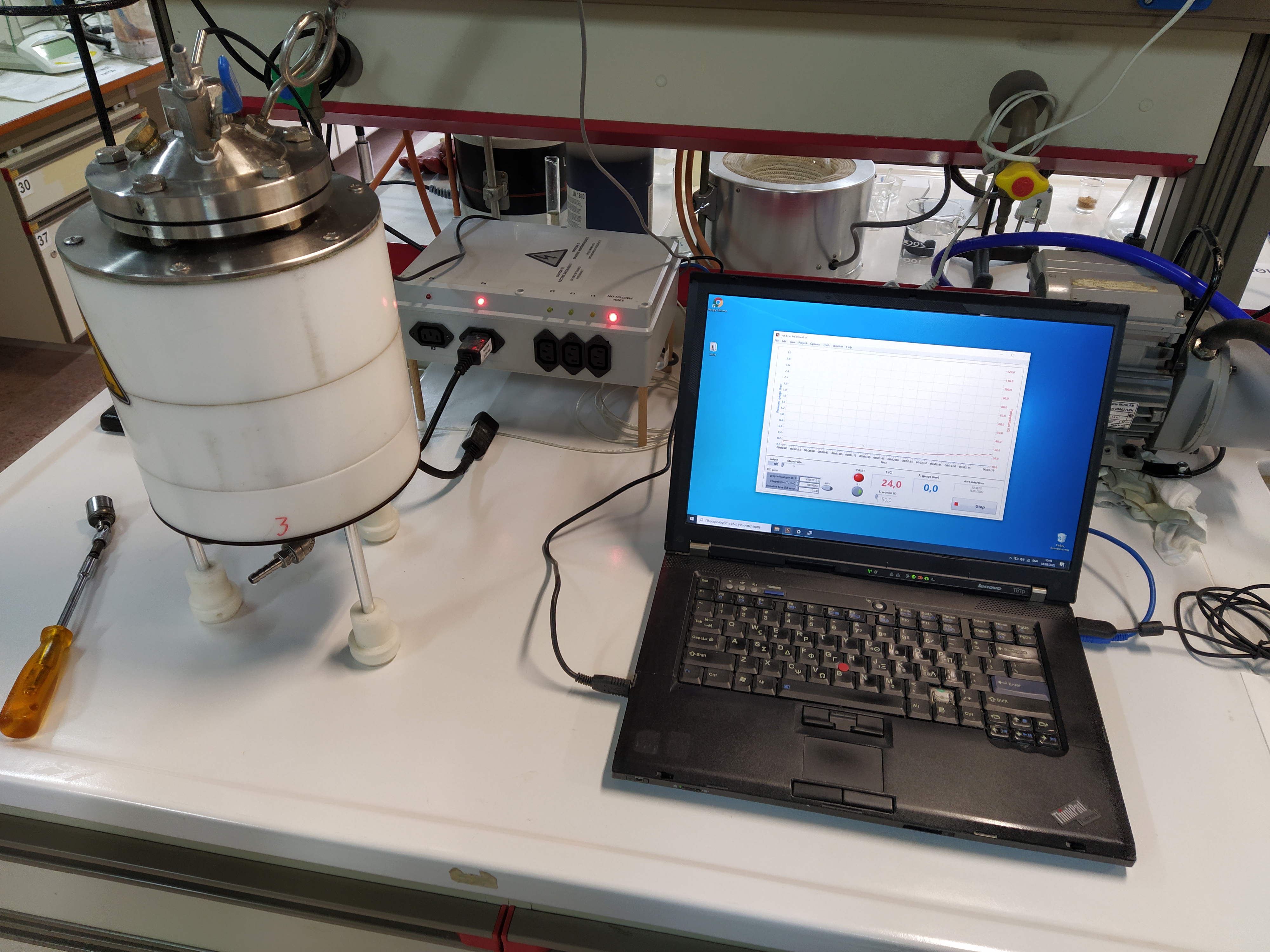

Laboratory Reactor

- Cylindrical, vertical, made of 316SS stainless steel

- Volume: 1.2L

- 2 integrated heating coats - 1.5KW(bottom & walls)

- Cooling circuit

- pressure or vacuum mode

- PT100 temperature sensors

- Analog pressure sensor -1 to 24bar

- Maximum pressure: 25 bar (abs)

- PID temperature / pressure control via standalone panel or via PC/Labview

- Possibility of application additional condensing parts or properties control (Up to 24bit Analog to Digital conversion)

- Ability to adapt to testing machines for precise control of pressure and thickness

Reactor in impregnation mode

Reactor in hydrothermal treatment mode

Flame spread test apparatus

- Controlled heat-flux profile with calibrated Gardon-type sensor

- Ceramic radiant panels

- Pilot-flame

Flame spread test apparatus

Ingnitabillity testing system (cone heater)

- PID controlled cone-heater

- Determination of ignitability

- Thermogravimetric analysis

- Ignition with or without pilot-flame

- Calibrated heat-flux sensor 0-100KW/m2, water cooled, Gardon-type

- Testing according to ISO5657 (165x165mm) or smaller (up tp 25x25mm) dimensions

Ignitability testing device (cone heater)

Single pellet die press

- Pellet diameter: 10mm

- Adjustment on test machines for precise control of densification pressure and thickness

- PID control of desification temperature (20-200°C)

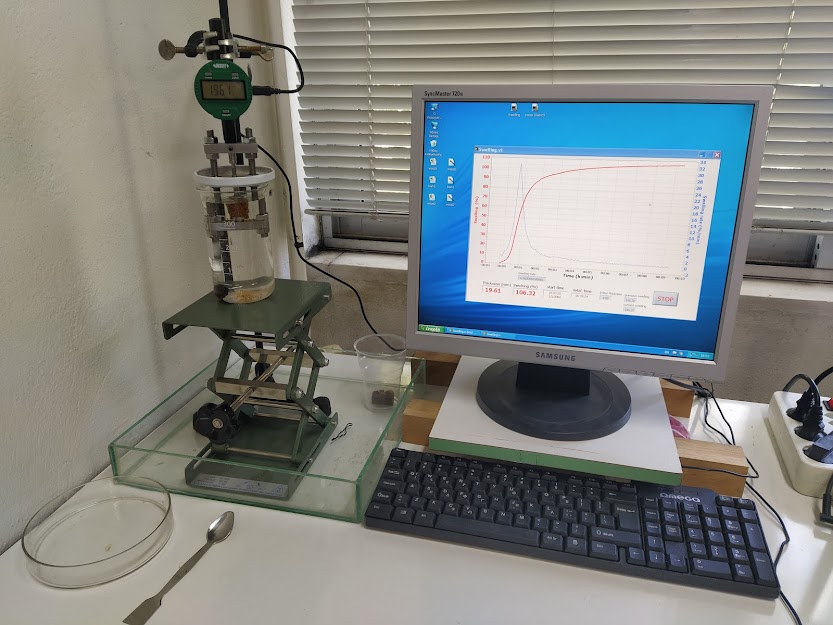

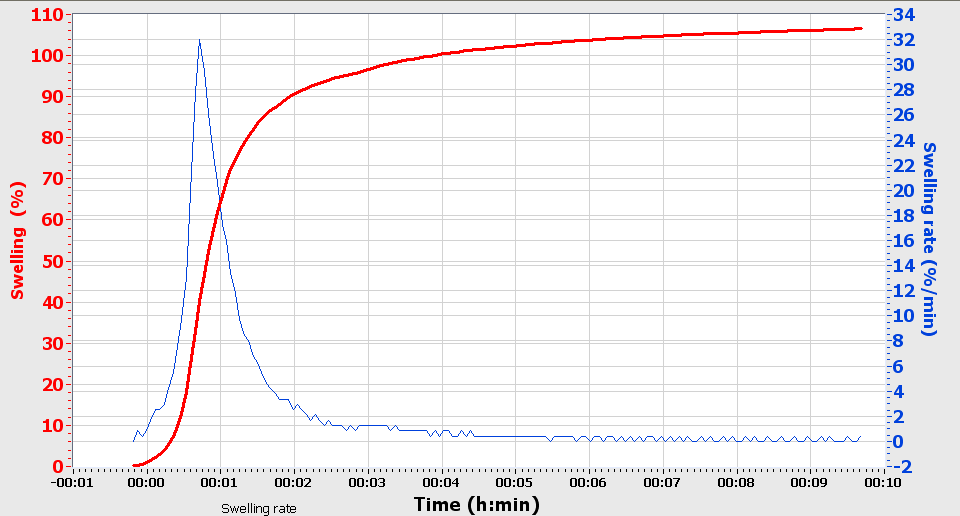

Swelling kinetics analysis system

- Open or closed system, temperature control

- Custom made software for acquisition and analysis

- Capacity of measuring various materials and dimensions

Swelling kinetics of wood biomass pellet

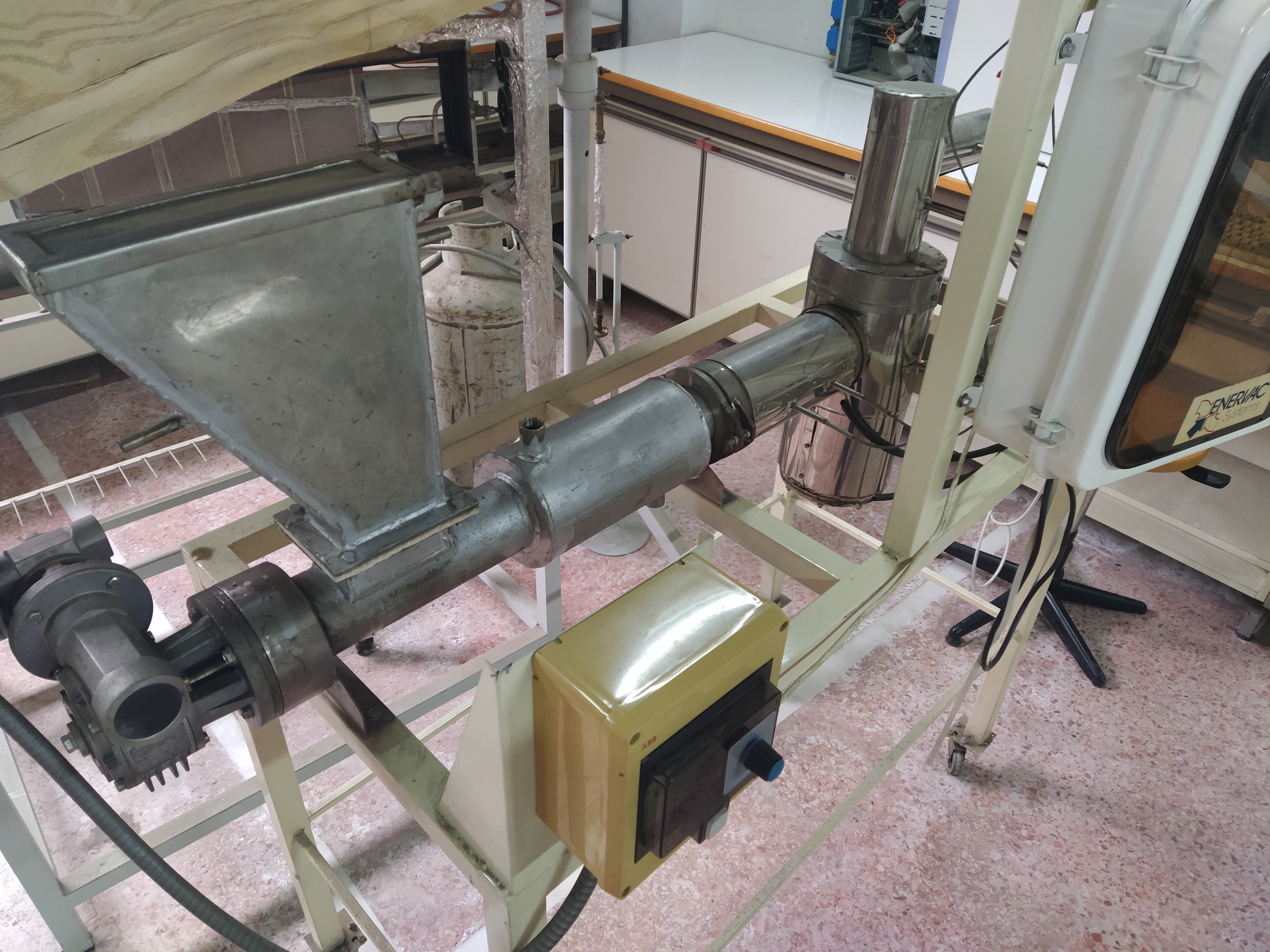

Biomass pyrolysis reactor (Auger)

- Controlled feed rate

- Stainless steel cylindrical reactor φ6 x 30cm

- 2-zone heating 0- 700C , PID controlled

- Custom made control software

- Seperate solid/fluid exit

- Pre-heating or pre-cooling of biomass

- Carrier gas feed control

Pyrolysis reactor